Value, identity and materiality

Good CMF sits at the intersection of creative, technical and commercial disciplines, defining how products communicate value, identity and materiality through their physical expression.

Today, its value extends even further: CMF has become a core mechanism for ecodesign, where material choice, surface treatment, and colour strategy directly influence environmental impact and product longevity.

Sustainability is a brand's strongest lever

Environmental consciousness is reshaping consumer loyalty.

In recent years, shoppers have increasingly sought products that reflect their environmental values, finding personal fulfilment in purchases that align with their beliefs.

Millennials lead this charge: nine in ten would abandon familiar brands for those showing stronger ethical commitments. Gen Z takes this further, viewing brand loyalty as secondary to corporate responsibility. As this generation assumes majority purchasing power, environmental and ethical practices will shift from competitive advantages to baseline business requirements.

Is CMF the understated champion of impact reduction?

Maybe…

CMF is certainly a strategic driver of sustainability, enabling lower embodied carbon, improved recyclability, and extended product lifecycles without compromising brand integrity or market appeal.

Colour

The Plastic Packaging Tax (PPT) is driving adoption of post-consumer recycled plastics.

As designers know well, working with PCR means confronting muddy base tones that dull vibrancy, batch variations that disrupt consistency, and random inclusions that threaten clean aesthetics. Yet, perhaps consumers are ready to read imperfection as integrity.

For years, speckles served as sustainability’s visual shorthand, suggesting bio-polymers, waste-derived materials, circular systems. Biopolymers reduce carbon footprint, true. But they introduce complications: durability questions, toxicity concerns.

Lower carbon tells part of the story, not all of it.

The move towards decorative-reduction is less about trend and more about demonstrating authenticity and purpose.

Material simplification streamlines end-of-life processing. Smart PCR masterbatch engineering allows aesthetics and recyclability to work together, cutting Scope 3 emissions while preserving brand expression.

Mastering material selection

Material selection is the most direct interface between CMF and ecodesign.

Designers must increasingly prioritise PCR, bio-based, or mono-material solutions to reduce resource extraction and facilitate end-of-life processing.

With 30% PCR now a baseline, designers navigate cosmetic constraints and performance trade-offs inherent to recycled polymers. Increasing recycled content means that materials are harder to process/control which can consequentially lead to an increase in scrap rates and spikes in downstream impact.

Light-weighting, although not strictly a true CMF consideration, will typically have a greater role to play in reducing your impact than switching to a bio-polymer.

Finish

Finish decisions carry significant ecological implications.

Traditional secondary decorative coatings (such as electroplating or solvent-based paints) often require energy-intensive processes, emit VOCs upstream and complicate – or even eliminate – recycling downstream.

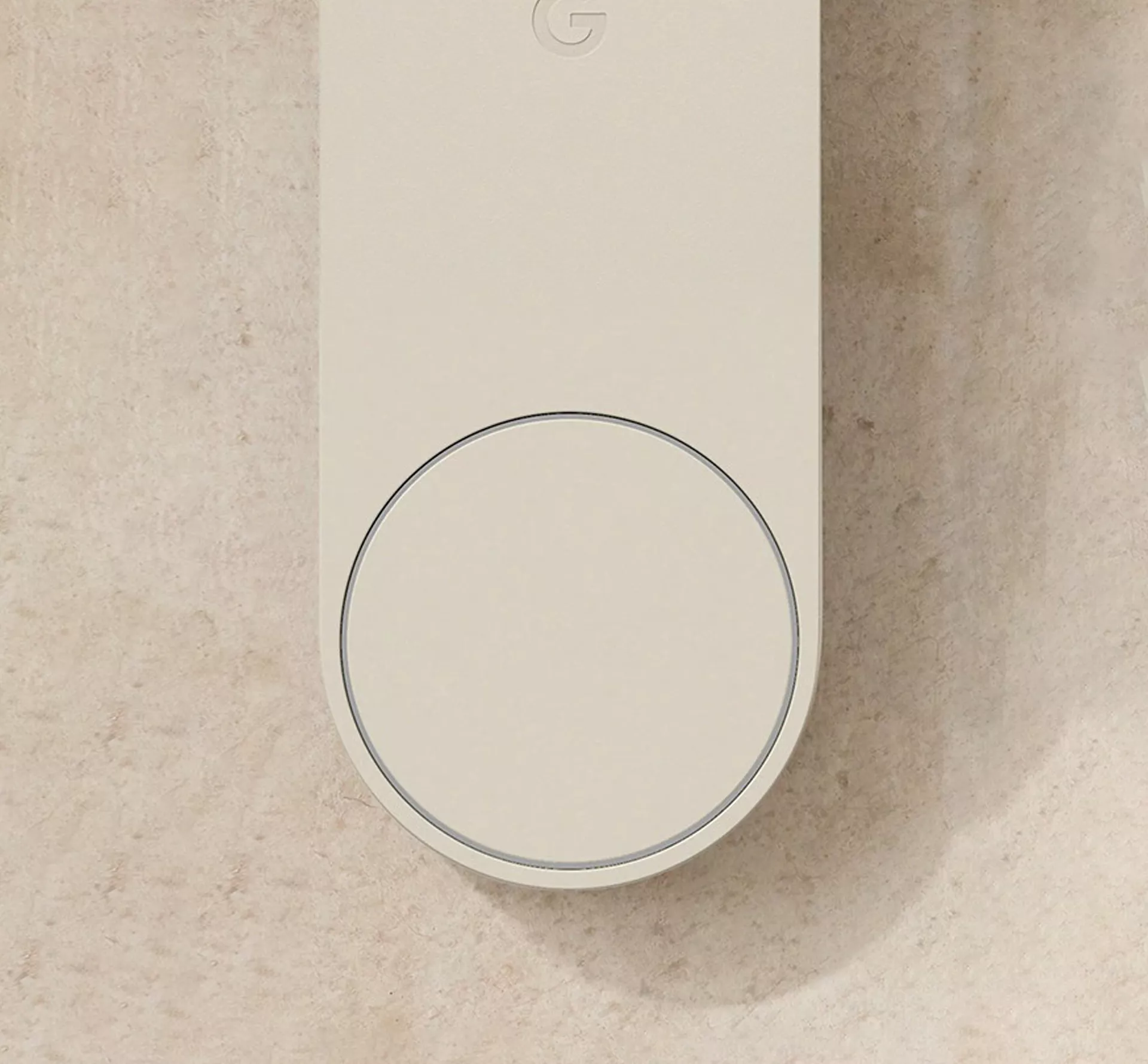

Low-VOC water-based coatings offer alternatives, but surface texturing (EDM), or finish-free approaches allow products to maintain durability and aesthetic appeal while reducing total environmental impact.

Micro-texturing, for instance, leans into the lower lustre surface gloss properties of PCR grades and can provide scratch resistance or a tactile quality without additional coatings, extending product life.

Takeaways for sustainable CMF

By treating CMF as a functional and ecological strategy, industrial designers embed sustainability into the sensory and visual identity of products rather than as a secondary consideration.

Colour

Learn to love a muted colour palette, darker hues and smokey-clears rather than high clarity translucency.

Material

PCR (PIR), mono-materials and light-weighting are the linchpin to lowering impact.

Finish

Eliminate or minimise secondary decorative treatments (unless parts can be separated at point of disassembly), celebrate the tactility of micro EDM finishes.